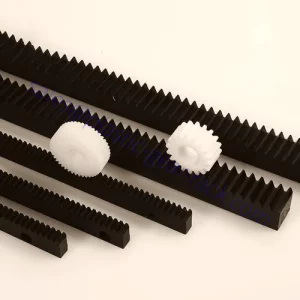

Plastic Gear Rack

When manufacturing plastic gear racks, because of their bar shape, often bending results. In these cases, corrective processes using presses are often employed.

Factors to Consider When Buying a Plastic Gear Rack

An important factor to consider is the pressure angle. The rack should be 14 1/2 degrees or less. Any spur gear greater than 20 degrees will not work properly with the rack. In addition, the center distance variation of the plastic rack and pinion gears should be minimal, which is critical for a specific application. Some racks and pinions can be modified to suit specific applications, such as when the rack must be cut to length. Likewise, the length of a single piece of the rack should not exceed three thousand millimeters. If longer lengths are required, multiple docking rails may be required.

Design and Application Examples of Rack and Pinion Mechanisms

Gears transmit power by turning a gear to move the gear with which it meshes. On the other hand, in the case of plastic rack and pinion gears, the combination of a rack in the form of a rod tension gear and a small diameter gear (pinion) converts rotary motion into linear motion to transmit power. For example, in the case where the pinion is stationary and the rack is moving, the pinion is usually connected to the output shaft of the motor. The driven side of the frame is supported by a separate structure of mechanical elements. The repetitive rotational motion of the pinion produces the repetitive back and forth motion of the rack.

Advantages of a Plastic Gear Rack

Plastic racks and pinions, and nylon gear racks are made of high-performance materials such as MC nylon and polyacetal. These durable polymers provide significant wear and noise reduction. These shelves are widely used in various industries. They are lightweight, corrosion-resistant, and rust-resistant, making them a great choice for larger productions. In addition, they offer excellent performance and low maintenance costs. Also, they do not require lubrication. They are also easy to operate and require no maintenance or replacement, making them ideal for large-scale operations.

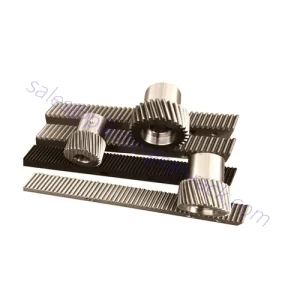

Gear Rack

An important consideration when choosing a china plastic gear rack and pinion is the amount of backlash it can handle. The backlash of the china rack should be no more than 0.5%. Any value above this will result in premature wear. To ensure your china plastic gear rack and pinion have no backlash, check the milling or grinding of the gear teeth. If you cannot determine the correct amount of clearance, use a scale to measure. If you need very tight backlash tolerances, a particular order is required.

Another consideration is the angle of rotation. The gear is connected to the rack by a key. A sleeve bearing supports the shaft of the gear. Racks and pinions are usually helical and require more creativity in design and application. If you’re looking for a more traditional approach, you might consider a rack with square shafts instead of a round rack.

Select Plastic Gear Rack and Pinion

Plastic Gear Rack for Sale

If you need a customized product, or the product you need is not found on our website, don’t worry; more of our products are still being uploaded. You can contact us directly by email, we will reply to you within 24 hours!

-

CNC Machine Customize High-Quality High Impact-resistance Mc Nylon Plastic Gear

-

Custom Nylon Gear Rack OEM Manufacturer Machining Plastic Rack

-

Customized Machining Plastic or Stainless Steel Straight Pinion Plastic Gear Racks

-

Engineering Plastic Injection Nylon Plastic Gear Rack Low Noise Plastic Rack

-

Good Glide Characters Customized Nylon Spur Gear Plastic Gear Manufacturer

-

High Precision CNC Machine Nylon Plastic Gear for Transmission

-

High Precision Nylon Plastic Gear Racks Pinion

-

Plastic Gear Rack and Pinion Nylon Gear Rack for Sliding Gate

-

Steering Gear Rack Plastics Nylon Plastic Gear Rack

Application

Q & A

Q1. When can I get the price?

A: We usually quote within 24 hours after receiving your inquiry. If you are urgent, Please call us or let us know in your email so we can prioritize your inquiry.

Q2. How long is the lead time for the mold?

A: It all depends on the size and complexity of the mold. Usually, the delivery time is 25-35 days. If the mold is simple and insignificant, we can do it within 15 days.

Q3. I don't have drawings; how should I start a new project?

A: You can provide us with samples, and we will help complete the drawing design.

Q4. How to ensure product quality before delivery?

A: If you do not come to our factory and there is no third-party inspection, We will be your inspector. We will give you a video with details of the production process, including process reports, product dimensions, structural and surface details, packaging details, etc.